Enterprise Resource Planning (ERP) systems are crucial for managing all aspects of a manufacturing operation. However, the most suitable ERP system for an aircraft manufacturing company differs from that of a chemical production company. That’s because discrete manufacturing and process manufacturing have fundamentally different workflows.

Here’s a breakdown of the key ERP requirement differences:

Understanding Discrete Manufacturing

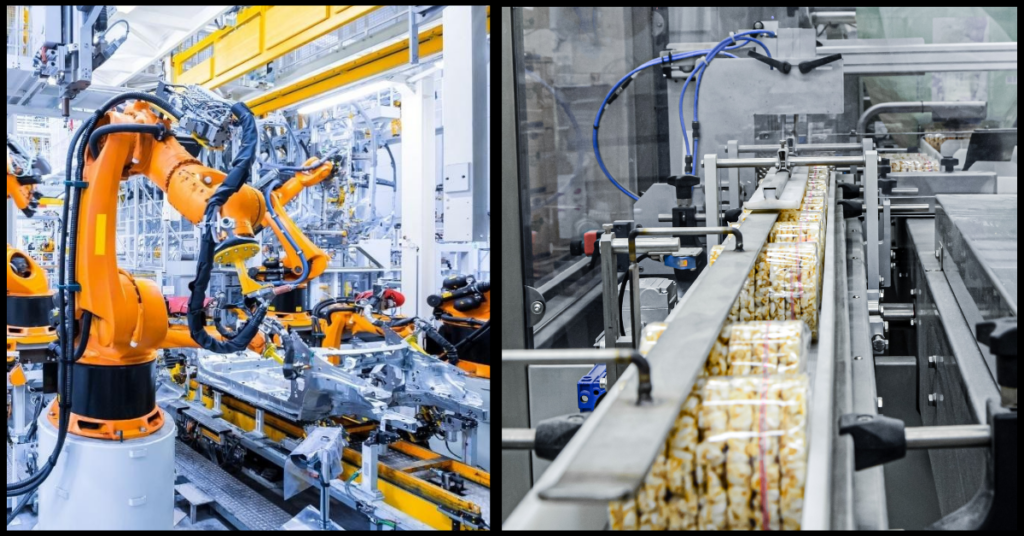

Discrete manufacturing deals with creating distinct, identifiable end products like cars, furniture, or electronics. Each unit is assembled from individual components using a Bill of Materials (BOM). These BOMs stay consistent, allowing for efficient production planning.

Key ERP Features for Discrete Manufacturing

Process manufacturing involves transforming raw materials through chemical reactions or physical processes. Examples include food & beverages, pharmaceuticals, and paints. Products are created in batches using formulas or recipes and may involve byproducts and waste materials.

Key ERP Features for Process Manufacturing

Project manufacturing and discrete manufacturing deal with distinct production processes, requiring different functionalities from their ERPs. Here’s a breakdown of the key differences:

Project Manufacturing vs. Discrete Manufacturing

Core ERP Requirement Differences

ERP Requirements Comparison: Process vs. Discrete Manufacturing

Feature | Process Manufacturing | Discrete Manufacturing |

Production Type | Continuous flow of materials | Distinct, individual units |

Core ERP Needs | Formula & Recipe Management, Batch Processing Control, Yield & Co-product Management | BOM Management , Inventory Control , Production Planning & Scheduling |

Inventory Management | Focus on raw materials & WIP (work-in-process) , FIFO (First-In, First-Out) crucial | Focus on finished goods & components, Real-time visibility essential |

Production Planning | Based on production recipes and capacity, Real-time adjustments for continuous flow | Production based on BOMs, sales orders, and MPS, \ Finite scheduling to optimize resource allocation |

Quality Management | Continuous monitoring of process parameters, Automated alerts for deviations | Quality control inspections at various stages |

Scalability | Recipes need to adapt to adjust production volume | System should handle variations in product configurations |